Condenser coil manufacturing in the UAE is a critical industry that caters to the increasing demand for efficient cooling systems. As a condenser coil manufacturer in the UAE, specializing in the design, engineering, and production of high-quality coils, plays a vital role in meeting the unique requirements of clients in Dubai and other parts of the UAE.

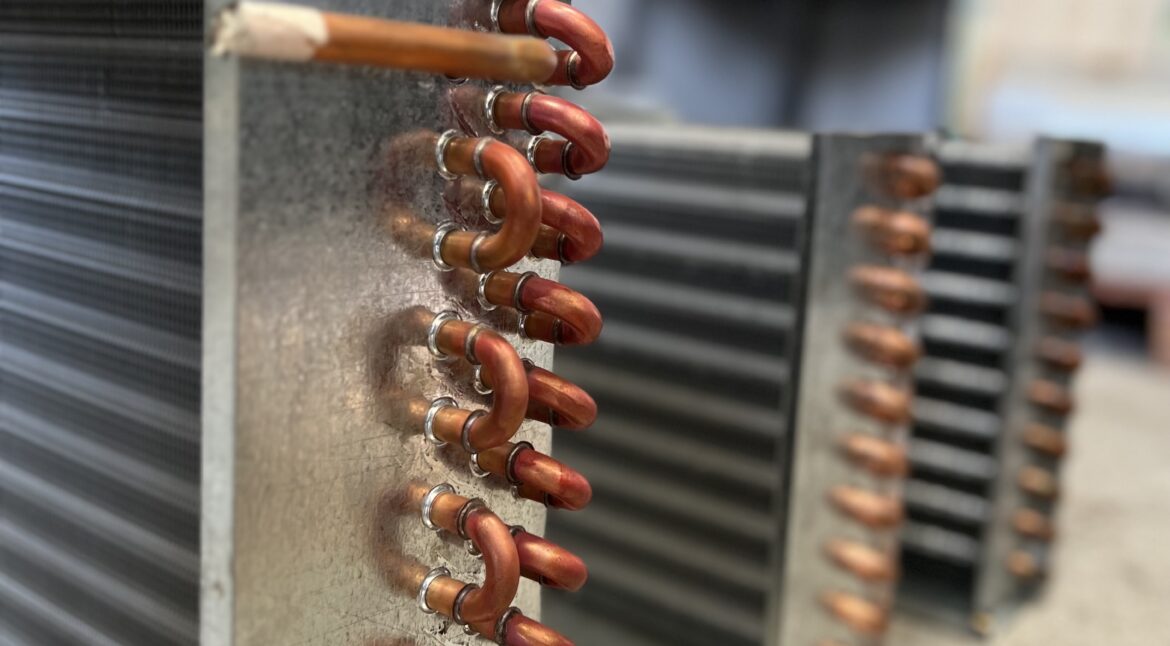

Basics of Condenser Coils:

Condenser coils enable the transition of hot, high-pressure refrigerant vapor to a cooler liquid state. This heat exchange process is fundamental to the refrigeration cycle, as it allows the system to remove heat from the conditioned space or refrigeration process. By effectively dissipating heat, condenser coils help maintain ideal temperatures and support energy efficiency in cooling systems.

Efficient condenser coil design and manufacturing are paramount for optimal heat transfer, resulting in improved energy efficiency, lower operating costs, and enhanced cooling performance.

Well-designed coils can withstand continuous operation, resist corrosion, and maintain their structural integrity over time. This translates to reduced maintenance needs, fewer system failures, and extended equipment lifespan.

Manufacturing Process for Condenser Coils:

The manufacturing process for condenser coils involves several stages that ensure the production of high-quality coils. Let’s take a closer look at each stage:

Design and Engineering:

The process begins with the design and engineering phase, where specifications and requirements are analyzed, and coil designs are developed using computer-aided design (CAD) software. Factors such as heat load, airflow, and space constraints are considered during this stage to optimize performance.

Material Selection:

The appropriate materials for condenser coil construction are selected based on factors such as heat transfer efficiency, corrosion resistance, and durability. Common materials include copper, aluminum, and stainless steel.

Tube Preparation:

Tubes are cut to the required lengths and prepared for assembly. This involves processes such as straightening, flaring, and expanding the ends for proper connections.

Fin Manufacturing:

Fins, which increase the surface area for heat transfer, are manufactured using state-of-the-art press machines. Fins are typically made of aluminum or copper and are precision-formed to ensure optimal heat transfer performance.

Assembly:

The tubes and fins are assembled by bonding or mechanically attaching the fins to the tubes, creating the coil’s core structure.

Brazing:

In some cases, brazing is performed to join the tubes and fins securely. Brazing ensures a strong, leak-free connection and enhances the coil’s overall structural integrity.

Cleaning and Inspection:

The completed coil undergoes thorough cleaning to remove contaminants and then undergoes comprehensive inspection to ensure quality and adherence to specifications.

Commonly Used Materials in Condenser Coil Manufacturing In UAE:

Different materials are utilized in condenser coil manufacturing based on their specific properties and applications. Here are the commonly used materials:

Copper:

Copper is widely employed due to its excellent thermal conductivity, durability, and corrosion resistance. It allows for efficient heat transfer, making it a preferred choice for high-performance condenser coils.

Aluminum:

Aluminum is lightweight, cost-effective, and possesses good thermal conductivity. It is commonly used when weight reduction and cost efficiency are priorities.

Stainless Steel:

Stainless steel is valued for its exceptional corrosion resistance, making it suitable for demanding environments or applications involving corrosive substances.

Advanced Condenser Coil Manufacturing In UAE Techniques and Technologies:

Condenser coil manufacturers in the UAE must employ advanced manufacturing techniques and technologies to produce superior coils. Some of these techniques and technologies include:

Precision Engineering:

Computer-aided design (CAD) software and advanced engineering techniques are utilized to ensure precise coil design and optimized performance.

State-of-the-Art Press Machines:

State-of-the-art press machines for fin manufacturing guarantee the highest quality fins with precise dimensions and consistent fin spacing.

Automated Assembly Processes:

Automated assembly processes enhance efficiency, accuracy, and consistency during coil production, ensuring reliable and uniform coil performance.

Quality Control Measures in Condenser Coil Production:

Quality control is a vital aspect of condenser coil manufacturing to ensure exceptional performance, durability, and reliability. Here are some common quality control measures:

Comprehensive Testing:

Condenser coils undergo rigorous testing procedures to verify performance, durability, and reliability. These tests may include pressure testing, leak detection, and thermal performance evaluations.

Compliance with Industry Standards:

Manufacturers ensure that their processes comply with relevant industry standards and regulations, guaranteeing that their condenser coils meet or exceed required specifications.

Traceability and Documentation:

Detailed records and documentation are maintained throughout the manufacturing process, enabling traceability and quality assurance. This includes documenting materials used, manufacturing procedures, and test results.

Custom Condenser Coil Manufacturing in Dubai:

Customized condenser coils tailored to specific requirements play a vital role in meeting the unique needs and challenges of various industries. Off-the-shelf coils may not always align perfectly with specific cooling system configurations, space limitations, or performance objectives. Benefits of custom coils include:

Optimal Performance:

Custom condenser coils are designed to maximize performance by precisely matching the requirements of the cooling system. This ensures efficient heat transfer, better temperature control, and improved system performance.

Space Efficiency:

Customization allows condenser coils to be tailored to fit within specific space constraints. This is particularly valuable in situations where available space is limited, such as in compact HVAC systems or industrial installations.

Enhanced Durability:

Custom coils consider specific operating conditions, materials, and environmental factors, resulting in enhanced durability and longevity, even in demanding environments or extreme temperature conditions.

Challenges and Solutions in Condenser Coil Manufacturing:

Condenser coil manufacturing can present various challenges. Here are some common challenges and innovative solutions:

Corrosion Resistance:

Coils may be exposed to corrosive substances, especially in industrial settings. Advanced coatings or appropriate materials with enhanced corrosion resistance ensure coil longevity and performance in corrosive environments.

Space Limitations:

Limited space availability in HVAC systems or industrial installations can pose challenges in designing and fitting condenser coils without compromising performance. Customized design solutions help overcome this challenge, ensuring efficient and compact coil configurations.

Heat Transfer Efficiency:

Achieving optimal heat transfer efficiency while considering factors like airflow, heat load, and system design can be complex. Computational Fluid Dynamics (CFD) simulations can optimize performance, airflow distribution, and system efficiency.

Addressing Unique Challenges in the UAE Market:

The United Arab Emirates (UAE) market presents specific challenges due to its climate and environmental conditions. Manufacturers address these challenges through innovative strategies:

Dust and Sand Particle Mitigation:

Specialized coatings, protective measures, and maintenance guidelines are implemented to mitigate the effects of the UAE’s arid climate, dust, and sand particles, ensuring optimal coil functioning.

Extreme Temperature Considerations:

Designing coils with advanced materials and optimized configurations enables them to withstand and perform well under the UAE’s high-temperature conditions, ensuring efficient heat transfer.

Environmental Considerations and Sustainability:

Environmental sustainability is a priority for condenser coil manufacturers in Dubai. Condenser coil manufacturing practices can have significant environmental and sustainability implications. Manufacturers focus on eco-friendly practices to minimize their impact:

Energy Efficiency:

Efficient condenser coils reduce energy consumption reducing environmental impact.

Resource Conservation:

Utilizing recyclable materials and optimizing manufacturing processes minimizes the carbon footprint and waste generation associated with coil production.

Condenser coil manufacturing is a complex process that requires expertise, advanced technologies, and adherence to quality control measures. Customization options, innovative solutions to common challenges, and a focus on environmental sustainability are key factors driving the industry forward. By understanding the intricacies of condenser coil manufacturing, industries can make informed decisions to ensure optimal cooling system performance and efficiency.

Collaborating with a reputable and specialized condenser coil manufacturer in the UAE, including Dubai, is crucial for meeting cooling system needs. If you require custom condenser coils tailored to your specific requirements, reach out to reputable manufacturers who specialize in delivering high-quality, customized solutions.

Best Condenser coil manufacturers

Manufacturers, such as Al Tabreed, have the expertise, experience, and advanced manufacturing capabilities to design and produce condenser coils that meet your exact specifications, ensuring optimal performance and efficiency for your cooling systems.

Remember, investing in quality condenser coils enhances system performance and contributes to energy savings, reduced maintenance costs, and extended equipment lifespan.

Al Tabreed Industries LLC as a Leading Condenser Coil Manufacturer in the UAE . We provide reliable and high-quality condenser coil manufacturing solutions.

With a solid reputation built on expertise and customer satisfaction, Al Tabreed Industries LLC has established itself as a trusted provider of condenser coils. We offer custom solutions tailored to specific space limitations, ensuring efficient and compact coil configurations.

Talk to us today for all your condenser coils needs.