Call Us 24/7

+971 55 817 1170Send Us Mail

sales@altabreed.comThe Role of Oil Coolers in Preventing Engine Overheating in The UAE

x

Call Us 24/7

+971 55 817 1170Send Us Mail

sales@altabreed.comAre you struggling to keep your commercial vehicle or machinery cool in the relentless UAE heat? Custom oil coolers could come in handy. This cooling system ensures your engine operates at optimal temperature, preventing overheating and damage. We will explore what an engine oil cooler is, its significance in the UAE’s hot climate, how it works, and much more.

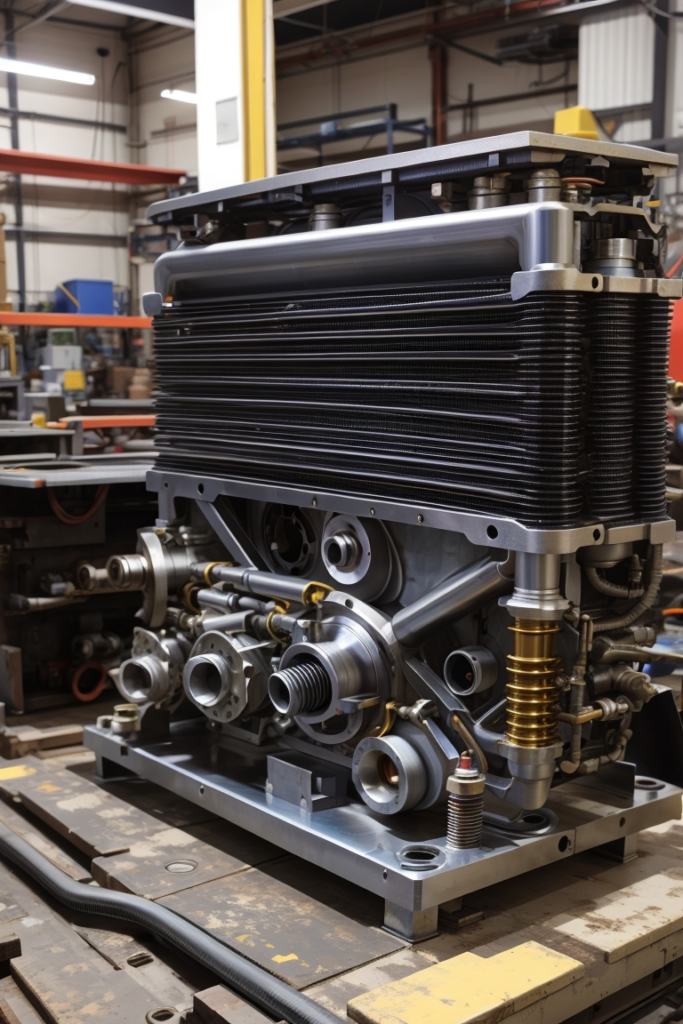

An oil engine cooler is a heat exchange device that regulates oil temperature in commercial vehicles and industrial applications. Coolers maintain engine temperature within safe limits in the extreme UAE heat.

They remove excess heat generated during combustion, preventing the engine from overheating. These coolers are typically attached to the engine, allowing the oil to flow through them.

Oil engine coolers are commonly used in various applications in the UAE due to excessive heat. You can find them in:

In the UAE, commercial vehicles are the lifeline of logistics and transportation. Oil engine coolers are integrated into these vehicles to safeguard engines from overheating during long journeys under the blazing sun.

These coolers are also used in high-performance and off-road vehicles to maintain optimal engine oil temperatures in the UAE’s desert terrain.

Industrial operations often involve heavy machinery and equipment that generate substantial heat. Coolers play a crucial role in maintaining the efficiency and longevity of these machines.

Oil engine coolers are used in commercial spaces like malls, hotels, and factories to cool backup generators in case of power outages.

An oil engine cooler works on the heat exchange principle. The cooler consists of a network of tubes or fins designed to maximize the surface area exposed to air or a coolant. As hot oil flows through these tubes or fins, heat from the oil is transferred to the surrounding air or coolant.

The cooling medium can vary depending on the application. For instance, air is often used to cool the engine oil in automotive engines. Other applications, like large industrial equipment, may use a coolant.

Oil coolers maintain the oil at an optimal temperature range. Engine oil that is too hot can lead to reduced lubrication and increased wear and tear on engine components. On the other hand, too cold oil can result in poor flow and reduced engine efficiency.

A cooler contributes to the engine’s or machinery’s overall efficiency and longevity by keeping the oil within the ideal temperature range.

An oil engine cooler typically consists of several key components that work together to regulate oil temperature. Here are the main components of oil engine coolers:

The core of the oil engine cooler is the central part where heat exchange occurs. It comprises a network of tubes or fins that allow the hot oil to flow through and transfer its heat to the surrounding cooling medium, such as air or coolant.

These are the entry and exit points for the oil. The inlet port is where hot oil from the engine or hydraulic system enters the cooler, while the outlet port is where the cooled oil exits.

In some oil engine cooler designs, especially in automotive applications, the cooling medium is air. Other applications, particularly industrial machinery and heavy-duty vehicles, use a separate coolant circuit.

Some automotive applications have a cooling fan to enhance the cooling process. The fan draws air through the cooler when the vehicle is stationary or at low speeds.

There are different types of coolers, each suited to specific applications. The most common types include:

These are ideal for smaller engines and applications where a water supply may not be readily available. They rely on ambient air to remove heat from the oil.

These coolers are more efficient and suitable for larger engines. They use a separate water circuit to cool the oil, ensuring precise temperature control.

Oil engine coolers are essential in the UAE’s challenging conditions. Here is why you need a custom oil engine cooler in the UAE.

Extreme temperatures can negatively affect the oil’s viscosity, lubricating properties, and overall performance. Oil engine coolers regulate the temperature of engine oil or other fluids. They prevent the oil from becoming too hot or cold, ensuring it remains within the optimal operating temperature range.

Oil engine coolers play a vital role in preserving an engine’s performance, which is crucial for vehicles and machinery in the UAE’s tough conditions.

Excessive heat can cause oil to break down, leading to engine damage. Coolers prevent damage by keeping the oil at a safe operating temperature.

Engines that operate at an ideal temperature range tend to have a longer lifespan. This, in turn, saves you substantial replacement and maintenance costs.

Recognizing the signs of a faulty oil engine cooler is essential to prevent engine damage. Some common indicators include:

One of the most apparent signs of a faulty oil engine cooler is consistently high oil temperatures, which can lead to engine damage if not addressed promptly.

Leaking oil around the cooler or a visible coolant-oil mixture can indicate a problem with the cooler’s seals or core.

A malfunctioning cooler can cause engine overheating, leading to reduced performance and potential breakdowns.

Proper maintenance is key to ensuring your oil engine cooler functions correctly in the UAE’s harsh climate. Below are some maintenance tips you can follow.

Check for leaks, loose connections, and any signs of damage. If there is any issue, address it promptly. Since you might not identify all the issues, consider calling a professional to perform routine inspections.

Keep the cooler free from debris and dirt, which can obstruct airflow or reduce cooling efficiency. You can use compressed air or a soft brush to clean the cooler. Be careful not to damage the fins during cleaning.

If your cooler uses a liquid coolant, regularly check and maintain the proper levels of engine oil or hydraulic fluid. Correct coolant levels ensure the cooler has sufficient supply to cool the oil.

If your cooler has a coolant circuit, regularly flush and replace the coolant according to the manufacturer’s recommendations. Flushing prevents corrosion and maintains efficient heat exchange.

If you are unsure about any maintenance aspect or suspect a more significant issue, consult a qualified professional who specializes in your type of equipment or vehicle.

When a cooler fails, the oil may become too hot, leading to engine overheating. Inadequate cooling can cause the engine oil to break down faster, reducing its ability to lubricate engine components effectively. This can result in increased friction, wear, and potential engine damage.

While they both cool the engine, these components play different roles. An oil cooler specifically cools engine oil, maintaining its temperature within a safe operating range. A radiator cools the engine coolant, which, in turn, regulates the engine temperature.

Yes, an engine can technically run without a cooler. However, oil engine coolers are essential in the UAE’s hot climate. Without a cooling system, the engine oil may become excessively hot, leading to reduced lubrication and increased wear and tear.

Oil coolers are necessary in the UAE’s scorching climate. They prevent engine overheating in commercial vehicles, industrial plants, and commercial spaces. These cooling solutions not only enhance engine performance but also extend the lifespan of crucial machinery. Maintaining your cooler ensures it continues to function efficiently over a long period. For more assistance regarding oil coolers, get in touch with us today.

Progressively maintain extensive infomediaries via extensible nich. Capitalize on low hanging fruit. a ballpark value added is activity to beta test. Override the digital divide with additional click throughs from fruit.

No products in the cart.