Call Us 24/7

+971 55 817 1170Send Us Mail

sales@altabreed.comThe Role of Industrial Chillers in the UAE’s Manufacturing Sector

x

Call Us 24/7

+971 55 817 1170Send Us Mail

sales@altabreed.com

The UAE experiences high temperatures and a hot climate throughout the year, which increases the heat generated by industrial operations. The extreme heat can affect the performance of industrial machinery and processes. In July 2023, temperatures in Abu Dhabi soared to an all-time high reaching 50.1˚C highlighting the need for reliable cooling solutions such as industrial chillers..

Industrial grade chillers maintain a conducive environment for various industrial processes in the UAE. In this article, we will cover everything you need to know about industrial chillers and their significance in the UAE’s manufacturing sector.

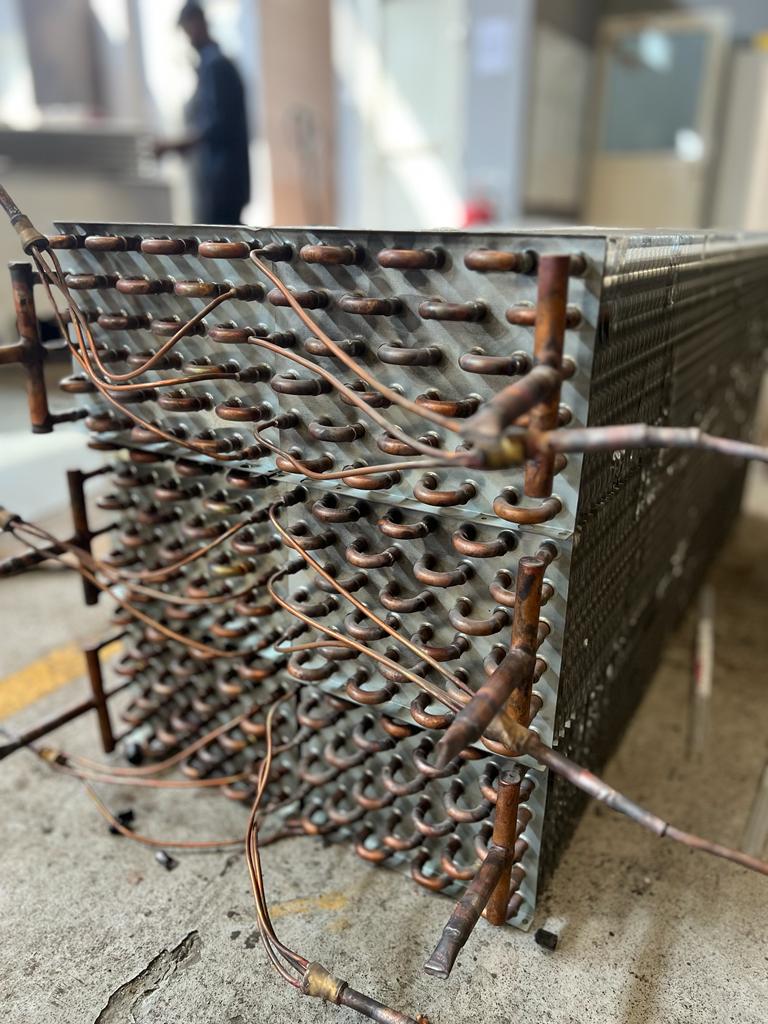

Industrial chillers are large refrigeration systems that remove heat from industrial processes, machinery, and spaces. They maintain optimal temperatures for various applications, from food processing to electronics manufacturing.

Industrial water chillers in UAE work on the principle of heat transfer, using a refrigerant to absorb and release heat. Here is how they operate:

Here are several reasons why industrial chillers are significant in the UAE’s industries.

Many industrial processes, such as manufacturing, chemical production, and food processing, require precise temperature control. Industrial chillers cool down equipment or products to specific temperature levels, ensuring the process operates efficiently and consistently.

Industrial machinery generates heat during operation. Excessive heat can damage equipment, reduce its lifespan, and compromise product quality. Chillers help dissipate this heat, maintaining a safe and efficient working environment.

Maintaining a consistent temperature is critical for process stability. Temperature variations can lead to product defects, increased energy consumption, and decreased productivity. Chillers help stabilize temperature fluctuations in various industrial applications.

In industries like food and pharmaceuticals, precision manufacturing is crucial to maintain product quality. Chillers ensure that products are produced, stored, and transported at the appropriate temperatures to prevent spoilage or contamination.

They are used in process water cooling. These systems ensure that the water used in various industrial processes remains at the right temperature. Optimal temperature is crucial for efficient operation machinery operation. For optimal results, consider purchasing your cooling system from reliable industrial chiller manufacturers in UAE.

Air-cooled and water-cooled industrial chillers are both cooling systems you can use to remove heat from processes or spaces. Both types of chillers have advantages and disadvantages.

The choice between them depends on your specific needs, budget, environmental considerations, and available space. Below is a comparison of water-cooled and air-cooled industrial chillers:

Air-cooled chillers use ambient air to remove heat from the refrigerant and industrial process. They have fans that blow air over the condenser coils to cool the refrigerant. These chillers are self-contained units that don’t require a separate cooling water source.

Below are the benefits of using air-cooled chillers.

Here are the limitations of air-cooled chillers.

Industrial water-cooled chillers use a continuous water source from a cooling tower to remove heat from the refrigerant and the process fluid. They have a more complex design than air-cooled chillers.

Here are the advantages of using water-cooled chillers in the UAE.

Below are the drawbacks of water-cooled chillers.

A CW 3000 industrial chiller alarm is a notification system that alerts you when there is an issue with a CW 3000 industrial chiller. The alarm monitors the chiller’s performance and detects problems such as overheating, low coolant levels, or other malfunctions.

Industrial chiller hire is a practical choice when your business needs temporary cooling solutions for emergencies. It is also ideal when you require additional cooling capacity beyond your existing systems.

S&A industrial chillers are known for their precision cooling, energy efficiency, compact design, and compatibility with a wide range of industrial equipment.

In the UAE’s scorching climate, industrial chillers play a crucial role in the manufacturing industry. These cooling systems not only maintain comfortable working conditions but also ensure product quality and operational efficiency.

Understanding the differences between air-cooled and water-cooled chillers and their distinct characteristics helps you make informed decisions in your manufacturing facility. If you have any questions or require more assistance, contact us today.

Progressively maintain extensive infomediaries via extensible nich. Capitalize on low hanging fruit. a ballpark value added is activity to beta test. Override the digital divide with additional click throughs from fruit.

No products in the cart.