Call Us 24/7

+971 55 817 1170Send Us Mail

[email protected]Everything You Need to Know About Heat Exchangers

x

Call Us 24/7

+971 55 817 1170Send Us Mail

[email protected]This is a guide on heat exchangers in UAE. It does not go into the technical details, but it provides an overview of what they are, their applications, and the types.

A heat exchanger transmits heat from one fluid to another. These fluids consist of gas or a liquid. The heat exchange process takes place without the two fluids mixing. For instance, in a furnace, a gas can transfer heat to water carried through pipes to warm your property.

Industrial heat exchangers help facilitate the processes that require efficient heating or cooling. These heat exchangers also help conserve energy and put it into good use. For instance, unwanted heat can be transferred from one point in a system to where it is needed. This can help you cut energy costs for your business.

Heat exchangers can be used in several sanitary and industrial applications. They can be used to maintain sanitary standards in the food and beverage industry.

Since food and beverages can be highly perishable, efficient exchangers are used to maintaining the ideal temperatures required to facilitate food and beverage processing. Heat exchangers help eliminate health hazards in foods and beverages through efficient heating and cooling.

Industrial heat exchangers can also be used in other applications like:

Heat exchangers vary according to their design, working principle, or material. Below are some of the main factors used to classify heat exchangers.

There are direct contact and indirect contact heat exchangers. In direct contact heat exchangers, the cold and hot fluids come into direct contact to produce a heating or cooling effect. These fluids are immiscible. Indirect contact heat exchangers contain a barrier that separates the hot and cold fluids from each other to prevent them from mixing.

Industrial heat exchangers can also be categorized according to the state of the fluids used to facilitate heat transfer. These fluids include:

Heat exchangers have different flow arrangements. Flow arrangement is the direction that the fluids follow in a heat exchanger. The following are some of the different flow arrangements in industrial heat exchangers.

To be effective, your brake linings should accomplish the following:

In parallel heat exchangers, both the warm and hot fluids flow parallel to each other and in the same direction.

The hot and cold fluids enter in opposite directions and move towards each other. These types of exchangers are often the most energy-efficient.

The hot and cold fluids move perpendicularly to each other, often crossing paths.

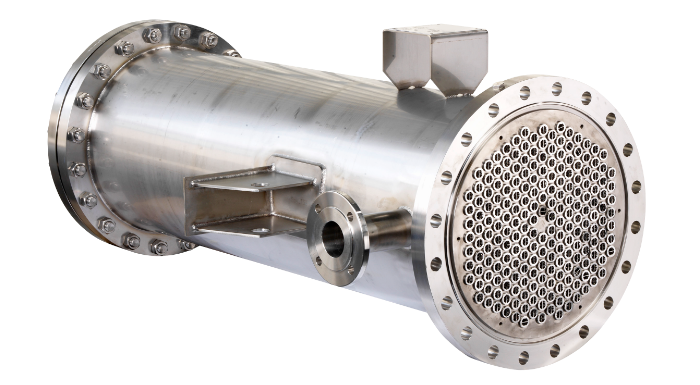

They contain a set of metal tubes through which one fluid flows and a sealed shell where the second fluid flows, facilitating heat transfer. The fluids can either be gases or liquids.

The fluids in these exchangers can flow parallel to each other, towards each other, or perpendicularly to each other. They generally have a simple design and have low maintenance costs. These exchangers are also cost-effective and can withstand high temperatures.

The downside of shell and tube devices is that they can take up a lot of space which could cause inconveniences. These devices also have low energy efficiency compared to other types of heat exchangers.

They contain a sequence of tubes with fins attached to the outer part of the tubes. The fins facilitate heat exchange between the fluid inside and outside the tubes.

These fins increase surface area, allowing a faster heat transfer rate. The fins increase the heat transfer surface area between the tubes and the fluid located outside the tubes.

They mainly use air as a medium of heating or cooling. They are also used to recover waste heat. These efficient thermal exchangers can be used to exchange heat between air and a viscous liquid.

The fins used in these thermal exchangers have several designs and can be made of different materials depending on their application. Some of these materials are used to make custom thermal exchangers resistant to corrosion. These materials include:

They can be designed not to take up too much physical space. This is because the number of tubes required could be reduced since the fins provide adequate surface area. With a smaller exchanger, you can cut installation costs.

It can be difficult to easily clean and maintain finned tube air thermal exchangers. However, you can use chemical cleaning to clean your heat exchanger.

They contain a sequence of gasket plates arranged on top of each other, allowing fluids to flow between them without mixing for effective heat transfer. The medium of heat transfer that is mainly used is a liquid.

The plates in these exchangers provide a large surface area for efficient heat transfer. The plates also increase the speed at which the fluids change temperature. Gaskets are used for sealing and directing the flow of fluids in the thermal exchangers.

Gasket plate exchangers are commonly made of the following materials.

The fluids in these exchangers can either flow in the same direction or towards each other. Gasket plates are easy to clean and maintain due to their simple design. These heat exchangers can also be easily modified by adding or removing extra plates.

Gasket plate heat exchangers can be prone to leaks. These thermal exchangers also limit the temperature difference between the two fluids. They can be costly and not suitable if you are working with a limited budget.

They are made by welding two sheets of metal using laser or resistance welding to achieve a pillow-like shape. This type of heat exchanger contains spaces within which the fluids flow and facilitate heat transfer.

There are two types of pillow plates namely:

The medium of heat transfer used in pillow-plate thermal exchangers can either be a liquid or a gas. These exchangers can be used in the food or pharmaceutical industries. You can use them in applications such as:

Their construction reduces pressure loss and increases heat transfer rate. These cooling devices are mainly made of steel which makes them corrosion resistant. They can also withstand high temperatures and pressure, making them suitable for fluids with a large temperature difference.

These devices are easy to clean and maintain, making them particularly suitable for sanitary applications involving food and beverages. Pillow plates are very flexible, making them easy to mold into different shapes for various applications. Pillow-plate thermal exchangers don’t take up too much space.

An Adiabatic wheel heat exchanger consists of a rotating wheel with threads and an intermediate fluid. The wheel rotates and extracts or transfers heat. The threads increase the surface area for effective heat transfer. The two fluids are separated by the wheel, preventing them from mixing. This heat exchanger is suitable for heat transfer between either liquids or gases.

These industrial thermal exchangers can be used in several applications, such as:

They have a unique design which makes them suitable for transferring heat between gases.

They are important in streamlining industrial processes. Below are some of the reasons why they are crucial.

They ensure food is safe for consumption. The heating and cooling processes help keep food and beverages safe from bacteria that cause spoilage or contamination. Heat exchangers provide the ideal temperature required to process or store food safely.

They effectively maintain temperatures at the required levels for several industrial processes and commercial applications. Industrial plants and factories require heat exchangers to maintain the optimum temperature required in machinery and chemicals.

In commercial applications like air conditioners or heat pumps, heat exchangers can be used to maintain the ideal temperature required for your comfort.

They are essential components of your industrial processes. Cooling manufacturing plants, cooling spaces, power generation, milk pasteurization, petroleum refining, and many other processes rely on efficient heat exchangers. There are many types of industrial heat exchangers you can choose from depending on your needs. If you require more assistance, don’t hesitate to contact us today.

Progressively maintain extensive infomediaries via extensible nich. Capitalize on low hanging fruit. a ballpark value added is activity to beta test. Override the digital divide with additional click throughs from fruit.

No products in the cart.